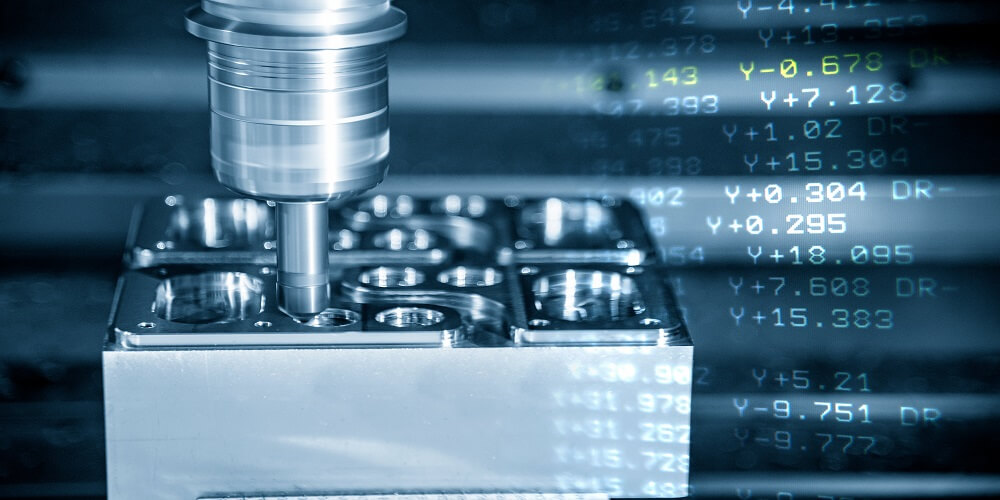

We make use of machined parts in our day to day activities, especially in highly technical industries. There are various methods of machining. CNC Machining which uses CNC parts is just one of those methods.

During the CNC Machining process, the size or the shape of raw material is reduced to the desired measurement. Materials that normally undergo this process include metals, plastics, and ceramics.

A greater percentage of the population depends on machined items. These items could be simple or complex designs.

Benefits of CNC Machining

There are many types of Machining processes in use today. However, most industries prefer using CNC Machining because of the following reasons

1. It is widely applicable

CNC Machining can be used on all kinds of materials ranging from plastics, ceramics, and metal. It can even be used in Machining glasses and wood.

This versatility is something other Machining processes are yet to achieve.

2. It is extremely accurate

Every machined part manufactured by CNC technology is totally reliable. This is because all the aspects of Machining accuracy are credited to every CNC machined part.

The aspects include shape accuracy, dimensional accuracy, and position accuracy. However, different materials machined under the same condition might differ in their accuracy level.

Different accuracy levels are usually obtained due to differences in tolerance levels. Machine parts with a larger tolerance range are more likely to be accurate.

3. It is time effective

Unlike other parts, sorting and assembling CNC machined parts are usually fast and easy. They have been pre-programmed with attributes that make this possible.

For example, if a manufacturing company needs a particular machined part, they can simply place an order. This order will contain desired specifications.

The operators will be able to design the part just the way you want. This feature has been made possible in recent times using the latest CNC technologies.

This approach not only makes your work faster, but it also saves you a lot of money.

4. It is easily customizable

This is one of the biggest advantages of CNC Machining over other Machining methods. For instance, when you use a diamond to machine aluminum parts, the aluminum parts will end up with the same accuracy and light-reflecting effect.

Also, diamond tools can be used to increase the transparency of plastic parts. It provides a better polishing effect for plastic parts.

5. No minimum quantity

Every CNC machined part is of high quality and there is no minimum quantity you are mandated to buy. CNC Machining is flexible, that is why customers love it.

It makes no sense that manufacturers will decide the number of products you can buy. After all, not everyone needs as much as hundreds of products. If you need just 20 pieces, you shouldn’t be forced to buy more.

With CNC machined parts, you can buy as little as you want. CNC Machining technology enables you to select various sizes and shapes of products at very affordable prices.

Conclusion

Having gone through these benefits, you now see why manufacturers prefer to use CNC Machining for their Machining operations.

One big disadvantage of this process though is that machine parts produced through CNC Machining are usually expensive.