CNC Programming (Computer Numerical Control) is involved in the manufacturing process. Currently, it is used by manufacturers to make program instructions that aids computers control machine tools. While enhancing automation and flexibility, the CNC machine connects with G-Code. Read here for more insight on the same.

What is a G-Code?

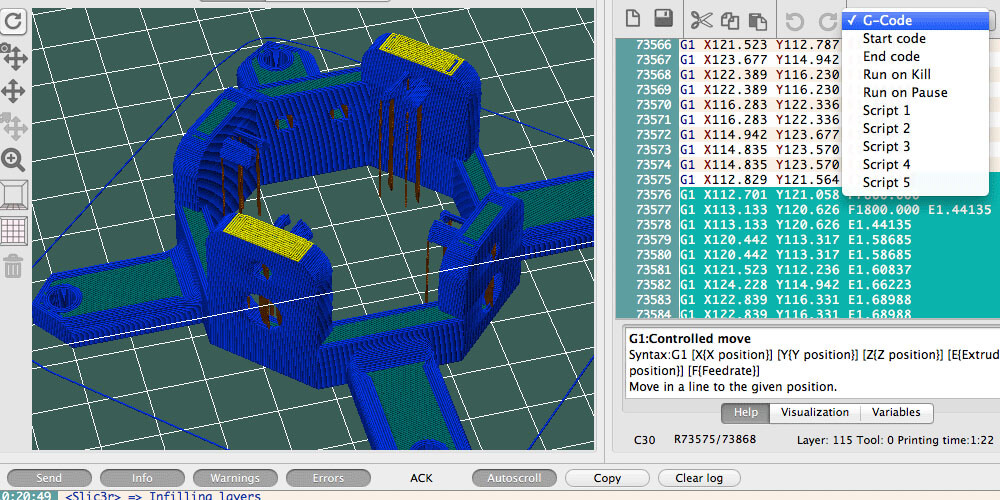

A G-Code is a primary language that aids in controlling CNC Machines. It is also another kind of CNC programming that other CNC programmers use together with a different type of CAM programming. The CAM programs create G-Code from a CAD drawing, but the end being G-Code.

G-Code standards and Dialects

There is an adequate amount of dialects and standards for G-Code. There are important details that one has to know to understand the G-Code’s dialects for your controller. Check them out in the next paragraph.

Different Dialects

G-Code dialects vary in different ways. Manufacturers have put up self-whistles to make a dialect top on the market. A few of the reasons include:

- Formatting-some permits have numbers with decimal points or trailing zeros.

- Support- each controller does not need support from all the G-Codes.

- Parameters and Macro Programming-many controls have limited capacities around Macro Programming. There are detailed differences in the working of Macros. G-Codes need more information to perform their work.

- Mappings-Different G-Codes on various controls support similar functions.

Expressing Coordinates in G-Codes

To make it simple, the spaces between letters to its value is optional. Take the axis letter and add value.

G-Code cheat sheets with CNC Programming Weapons

Only ten g-codes are called MDI and can use CNC to perform manual machinist roles. This is a secret weapon for manual machinists. For a CNC beginner, some simple learning of the ten g-codes is essential.

The ten g-codes:

- S, M03, M07/M08control Spindle

- G01 Move while cutting

- F control feed rate

- G00 move fast in the air.

- M05 stops spindle while M09 stops coolant.

Four kinds of CNC Programming software will help you produce useful G-Code for the CNC machine.

- CAM Software

It is mainly used to convert CAD drawings. The 3D printers use “Slicers” software for the same work.

Features of a G-Code editor

- Program Revision

This feature aids in making mass revisions for programs

- Texting Editing

This feature explicitly decides the simple methods to edit texts for your program. G-Code Syntax is not the standard feature for a text editor.

- G-Code Simulator with Black-plotter

These features allow you to watch the G-Code Program for stimulation.

- Information and Power editing