We all press brakes right? You know, one of the most important elements of manufacturing. However, the press brakes you know now haven’t always been this way.

Over the years press brakes have evolved to become what it is right now. Amazing right? To understand the journey of press brakes and how they have come to be in the situation they are right now, we’ll take a look at its journey.

Let’s look at the history of press brakes through two important categories;

Systems

The history of press brakes can be traced to the 17th century. Then, press brakes were not as automatic as they may seem now. Most press brakes were mechanical. It was made up of a clutch, brakes, flywheel and a crank. It stayed this way for a while. However, the introduction of metal fabrication changed the way press brakes were used.

The press brakes needed to be more flexible. This, in turn, led to the use of hydraulic press brakes. However, the drawback was that the production levels dropped down a notch. However, this form of press brakes still controlled the market.

To deal with new orders of fabricated metals and customer’s preferences, the electric press brakes were created. This press brakes could go more than 600 inches each minute it worked. It also had very good bending speed which could go as low as 5 IPM. With these machines, it was clear that precision and effectiveness will become the hallmark of the manufacturing process.

The rise of Automation

Without the use of automation in the manufacturing industry, the operators of press brakes had a lot of work to do. They had to check the bending angles as well as perform tests of functionality and efficiency.

With the rise of automation in recent times, the work has gotten easier. Now, most press brakes can deal with small jobs in very large quantities. They can also adjust their bending angle to ensure greater precision.

The creation of portable press brakes makes the system even faster.

CNC press brakes.

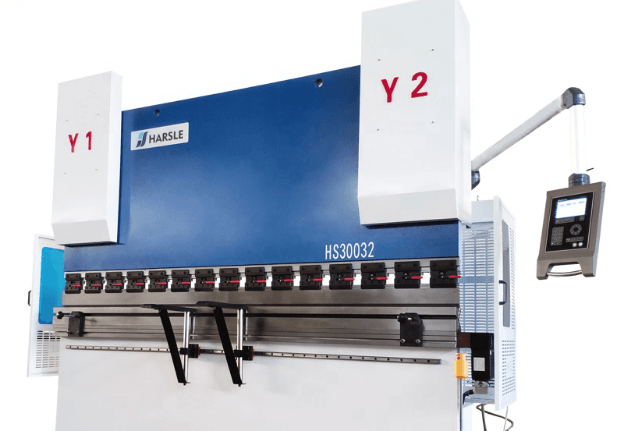

CNC press brakes are yet another branch in the development of press brakes. CNC press brakes are often seen to hold the edge when compared with other press brakes. The presence of more flexible programming, as well as lowered costs, might seem to be the main reason for this edge.

For this reason, most manufacturers tend to go for CNC press brakes now more than ever. It offers the best option in today’s world.

Final Thoughts

It’s been quite the journey for the manufacturing journey and CNC press brakes. However, the future holds so much more for press brakes.

However, if you are looking to tap into the press brakes industry, your best bet will be the CNC press brakes. They offer the best chance for efficiency and growth.

So join the bandwagon today and grow with the industry. It promises to be one big ride.