New markets and accessibility, coupled with demand for printing, are making laser printing famous in various markets. In the past, laser engraving was considered a process used explicitly by companies in the industrial sectors. These processes were useful in marking parts coupled with different tools and trophy shops to tailor products. Click here to learn more about flexo printing.

Today, numerous small businesses are emerging in addition to the rise of a maker movement. Therefore, laser engraving is blossoming into a rather profitable sector that takes a significantly small investment to be a significant part of.

Understanding laser engraving printing

Laser engraving printing refers to a technique used in printing lasers. After printing, the laser is used for engraving an object. In a broader category, laser printing involves color change because of molecular attraction and alteration, charring, as well as foaming.

Effects of laser printing in marketing

The impact of printing using lase is still being pronounced for rather explicitly designed materials for laser. These are such as laser-sensitive polymers as well as novel alloys.

Laser printing and engraving

Laser making and engraving are often used to cover a big spectrum of printing techniques, including branding and laser marking. The terms can interchangeably be used to mean the practice of laser engraving and printing. The machines used for laser printing and engraving are often similar in many ways, including the fact that they are automatic and easy to use.

Flexographic printing is also one major type of laser engraving printing. It is efficient in several forms. It is also extremely user-friendly in that you will not experience adverse challenges that come with laser engraving printing with other machine types.

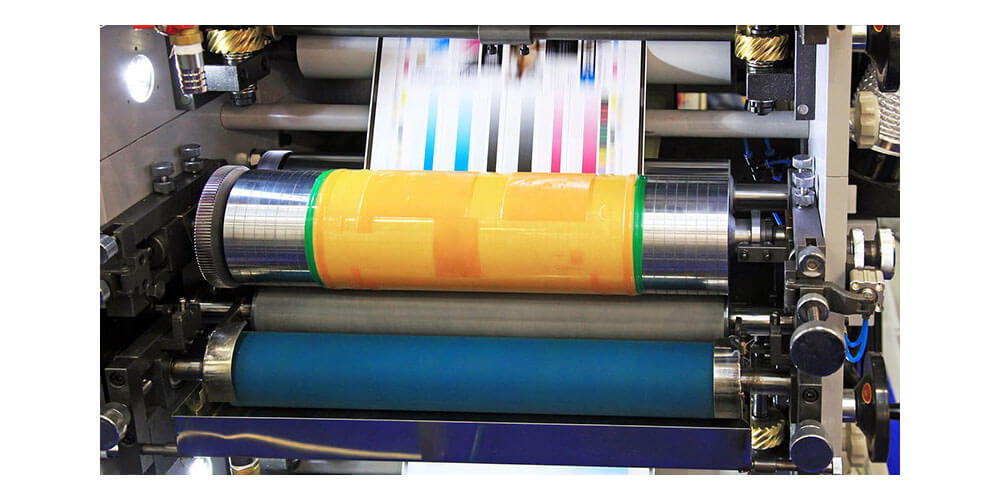

The flexo printing press is consistent. It is useful for medium to long-run applications of printing. Flexo is still one of the most popular printing methods on the market too. It uses pressers and photopolymer printing plates in imprinting images on broad surfaces.

The three pressers of flexo printing

Mainly applied for different labels as well as packaging, flexo printing offers a high-quality printing result simultaneously. The three interchangeable phases of flexo printing pressers include:

1. Merging offset printing with flexo printing in a single press

There are offset presses equipped with additional flexo units. The units can be readily available for flexible positioning. This is an ideal solution if you do not want to switch quickly

2. Embracing hybrid printing

Printing experts believe that flexo printing is definitely going to be the future of the printing industry.

3. Replacing offset printing as the main technology for printing

Replacing your offset printing with a flexo printing needs a short-term investment call since you should have a flexo presser. The transition is going to result in slightly reduced costs of production in the end.

Final Thoughts

When the name of printing processes, currently known as flexography, changed from the aniline printing, several printers thought the name had been adopted. The process was also primarily used for printing packaging materials. Today, flexo printing is a revered method of tech printing across the world.