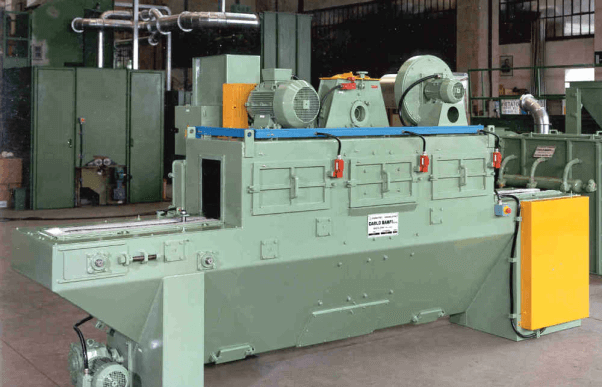

A shot blaster machine is a piece of equipment designed for repainting, polishing, and cleaning away contaminants from various surfaces. The process includes a collision of particles with a targeted surface. All particles are fired by a compressor aimed at the particular surface. As a result, the contaminant is scraped off the surface. The contaminants may be some old dried paint, rust, grease, or some other form of debris.

That’s pretty much it if you like a brief and concise explanation. But, if you want to know more, and perhaps you even consider buying one, keep on reading. Here are a few more things to know about shot blasting machines.

The importance of knowing about shot blasting machines

Purchasing a shot blasting machine without knowing how it works, the processes within the machine, its capacity, the expected workload, surface area coverage, and many others, is pretty much pointless and can lead to a poor investment.

It is prudent to choose a shot blasting machine only after learning about its air compression, it’s output, the treated surfaces, and pretty much everything in between relevant to the process of shot blasting.

Here is a list of things to consider when choosing a shot blasting machine:

- Consider the Type of Your Business

For example, if you have a business that deals with scrapping paint thin metals and cars, you will be best served by a lower power shot blaster machine. This is important because a high power machine can potentially eat away the metal surface along with everything else.

- Air Compressor Capacity

When determining the capacity of the air compressor always leave a 20% allowance so that it doesn’t run at its full capacity at all times. It gives the compressor some breathing space. It’s one thing for the compressor to run with 70 or 80% capacity, and another if it’s constantly running at its maximum. An air compressor constantly working under maximum load is more prone to defects and that’s a proven fact.

- Consider the Processing Ability of the Shot Blaster

If you plan to treat a large number of surfaces, then a semi-automatic or automatic shot blasting machine is recommended. In case your workload is not that extensive, consider getting a manual shot blasting machine.

- Cleaning and Dust Removal

Dust protection and cleaning efficiency are always important when choosing a shot blasting machine. Some machines come with powerful vacuum cleaners that take away all the dust automatically, while others don’t. This can be especially important if your workload is massive and continuous so that every minute counts. After all, you don’t want to waste too much time in cleaning and dust removal.

- Consider the Quality of the Inner Fender

The inner fender is a crucial part that determines the overall life of the shot blasting machine. So, make sure that it is a quality one that can serve you for many years.

In Conclusion

After choosing a shot blasting machine, and learning the facts, it is important to have an open conversation with the manufacturer so that you can get the best possible fit. Warranty, spare parts, and regular maintenance are areas that need to be discussed in detail with the manufacturer.