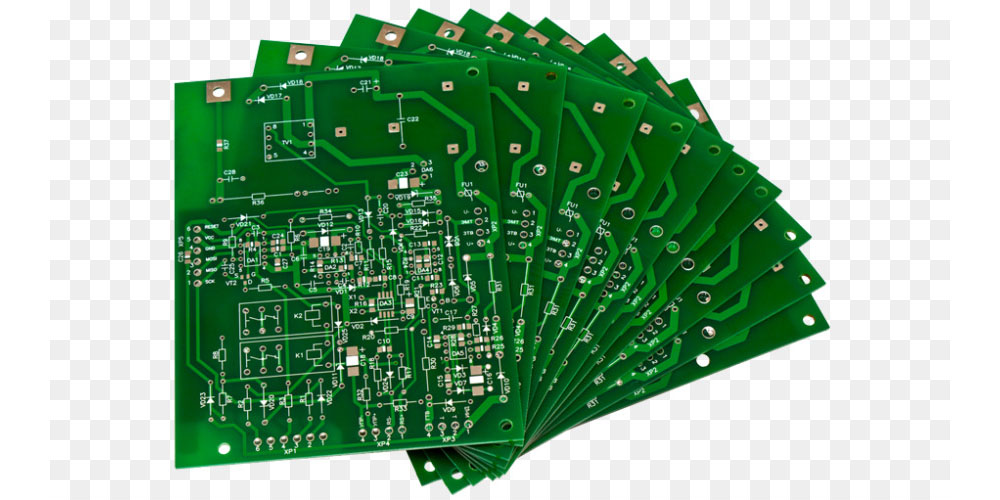

PCB manufacturing is a long and tedious process that needs doing with the utmost care so as not to miss any critical step or component. The manufacturing process gets done depending on the customer’s specifications of size and quantity needed. The whole process of PCB manufacturing, including assembly, prototypes, and component types, is explained in detail here; PCB assembly. This article gives an insight into the various advantages of PCBs.

Advantages of PCBs

PCBs are being preferred in the manufacture of various devices and equipment in multiple sectors. This preference is because of the following reasons;

1. Less Bulky

PCBs use advanced technology by making it possible to have highly used electronic equipment that is smaller yet still highly efficient due to copper in the PCBs instead of wires with the same results.

2. Time and Energy Efficient

PCB assembly is now less time-consuming than the old way of assembling components that would take twice as much time. Once the design gets chosen, many electronic components get manufactured in a short time.

3. Cost-Saving

Once the PCB has been designed and taken through testing, the production of electrical items in bulk becomes faster. Immediately a design is settled on; it gets used for subsequent product plans. Mass production is made possible using that one design. In the long run, it saves on costs for the industrial firm in question.

4. Fast Repair

When electronic devices and machinery get damaged due to wear and tear, it is easy to check and repair the defective component. The ease of repair is made possible due to the features being labeled on the circuit board, hence easier to track the wrong part. PCBs produced in bulk are the same in design therefore easily diagnosed and repaired.

5. Reduced Electronic Noise

PCBs produce little to no electronic noise when assembled correctly. Therefore the performance output of the circuit remains high grade. If any noise comes out, it emits in the form of heat or radiation.

6. Reliability

In the building of PCBs, there is strict assessment for errors done to ensure effectiveness and efficiency. This process is automated; therefore, the end product, the PCB, is deemed reliable.

7. Fixed Location

PCB location is fixed and known; therefore easier to identify electrical components of equipment and maintain them. The parts also are not easily moved when the circuit board shakes which, is an essential aspect in automobiles, such as cars.

8. Color-Coded

Different circuit boards have other color codes, making it easy to distinguish one from another, therefore easy installation with less confusion.

9. Long Shelf life

PCBs are getting made using metals such as copper and aluminum, which can withstand certain harsh conditions, making them fit for use in specific electronic devices. The use of such metals adds to the long lifespan of PCBs and, ultimately, the machinery made.

Conclusion

PCBs have found excellent uses in our environment. They make life easier and more automated, which makes it faster to assemble and disassemble different devices. The benefits of PCBs sure outweigh the disadvantages and continue giving reason to continue using them.